Monday – Friday: 9:00 am -8:00 pm

24/7 Emergency Service

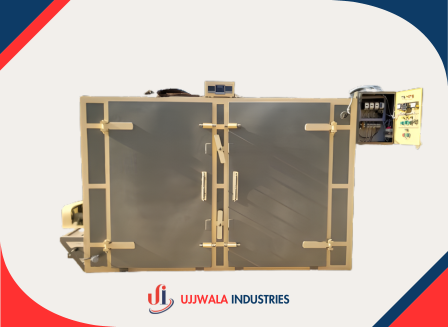

Chemical Tray Dryer

Use Of Product / Advantages

Tray dryers are widely used in chemical industries for various purposes due to their efficiency and versatility in drying processes. Some common uses of tray dryers in chemical industries include:

Drying of Solid Materials:

Tray dryers are commonly employed for drying solid materials, such as chemicals, pharmaceuticals, and food products. The trays allow for the spreading of the material in thin layers, facilitating uniform drying.

Drying of Granules and Powders:

Many chemical processes involve the production of granules or powders, which need to be dried before further processing or packaging. Tray dryers provide an effective means of achieving the desired moisture content in these materials.

Product Sterilization:

Tray dryers can be used for the sterilization of chemical products and laboratory equipment. The controlled temperature and air circulation help ensure that the products are free from microbial contamination.

Heat-Sensitive Material Drying:

Some chemical products are sensitive to high temperatures. Tray dryers offer the advantage of controlled and gentle drying, making them suitable for heat-sensitive materials that might be damaged by more aggressive drying methods.

Drying of Pharmaceuticals:

In the pharmaceutical industry, tray dryers are frequently used for drying active pharmaceutical ingredients (APIs), granules, and finished pharmaceutical products. The precise control over temperature and airflow is crucial in maintaining product quality.

Chemical Process Intermediate Drying:

In multi-step chemical processes, intermediates often need to be dried before moving to the next stage. Tray dryers provide a versatile solution for intermediate drying in various chemical manufacturing processes.

Drying Solvent-Laden Materials:

Tray dryers can be used to remove solvents from materials, ensuring that the final product meets quality and safety standards. The design of tray dryers allows for efficient solvent evaporation.

Research and Development:

Tray dryers are commonly used in research and development laboratories for small-scale drying experiments and feasibility studies. They allow researchers to optimize drying parameters before scaling up to larger production processes.

Agrochemical Drying:

In the production of agrochemicals, such as pesticides and fertilizers, tray dryers are employed for drying granules, powders, or finished products, ensuring proper shelf life and ease of handling.

Chemical Sample Drying:

Tray dryers are used for drying chemical samples in laboratories, facilitating sample preparation and analysis.

In summary, tray dryers play a crucial role in the chemical industry by providing a versatile and efficient method for drying various materials, from chemicals and pharmaceuticals to food products and research samples. Their adaptability and precise control over drying conditions make them a valuable asset in many industrial processes.

Applications

Tray Dryers are ideally suitable for drying chemicals, powders, granules, sludge from wastewater treatment plants for disposal , pigments, coatings, and paint formulations. etc. Heating is either by electric or steam or both combined. Various models are listed in this leaflet to suit customer requirements. Custom built models can be quoted on request.

Features

Drying Chamber: The main compartment where the material to be dried is placed. The size and shape of the drying chamber depend on the specific application and the type of dryer.

Trays: Tray dryers have trays, shelves, or racks where the material is placed in layers. Hot air circulates around the trays to facilitate drying.

Heating System: Can include electric heaters, steam coils, or other heating elements.

Air Circulation System: A fan or blower system circulates heated air or other drying mediums within the drying chamber. Proper air circulation is essential for efficient drying.

Heating System: The heating system generates the heat required for the drying process. Depending on the type of industrial dryer, this can include electric heaters, gas burners, steam coils, or infrared heaters.

Temperature Control: A temperature control system regulates the temperature within the drying chamber. This ensures that the drying process is conducted at the desired temperature for the specific material.

Humidity Control (Optional): Some industrial dryers incorporate humidity control systems to manage the moisture content in the drying chamber, especially in applications where precise humidity levels are critical.

Exhaust System: An exhaust system removes moisture or other by-products from the drying chamber, maintaining the desired conditions for effective drying.

Control Panel: The control panel houses instruments and controls for monitoring and adjusting drying parameters. This includes settings for temperature, humidity, and drying time.

Safety Features: Industrial dryers may include safety features such as over-temperature protection, emergency stop buttons, and alarms to ensure safe operation.

Variable Speed Control (For Some Dryers): Some industrial dryers offer variable speed control to adjust the drying process based on the specific requirements of the material being processed.

Insulation: Insulation material is used to minimize heat loss and improve energy efficiency during the drying process. This is particularly important for large-scale industrial dryers.

Technical Specifications

| Loading capacity | 10-12 Trays | 20-24 Trays | 25 Trays | 48-50 Trays | 96-100 Trays | 192-200 Trays |

|---|---|---|---|---|---|---|

| No of Doors | One | One | One | One | Two | Two |

| No of Blowers | Two | Two | Two | Two | Two | Four |

| No of motors / H.P.3 Phase 415 Volts . | 2/ 0.5 H.P.single phase 240 volt 1400 rpm | 2 / 0.5 H.P.single phase 240 volts 240 rpm | 2 / 0.5 H.P.single phase 240 volts 240 rpm | 2/1 H.P.Three phase 415 volts 1400 rpm | 2/1 H.P.Three phase 415 volts 1400 rpm | 2 / 2 H.P.eachThree phase 415 volts 1400 rpm |

| Electrical Heating Load for 100 ° C / 200 ° C / 300 ° C | 3kw | 6kw | 8kw | 12kw | 24kw | 36kw |

| Insulation in mm100 ° C / 200 ° C / 300 ° C | 50 | 50 | 50 | 75 | 75 | 75 |

| No of Trolleys | Rack System | Rack System | Rack System | One | Two | Four |

| Tray Size | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch |

| Trolley Dimension | Fixed Racks | Fixed Racks | Fixed Racks | Movable Trolley | Movable Trolley | Movable Trolley |

Featured Products

Product Brochures

Illuminating Lives with Quality Products for a Brighter Tomorrow.

Intas Pharmaceuticals

I recently purchased a Ujjwala Industries Tray Dryer Machine and I am very pleased with my purchase. The machine is well-constructed and easy to use. It is designed to quickly and efficiently dry a variety of items such as fruits, vegetables, and herbs. The temperature settings are adjustable and the machine is equipped with a timer.

Rashtriya metal industries ltd

Best Vendor i have ever got till date. He is very genuine, honest person, gives me delivery on time also he is continuously taking my follow-up post delivery whether I have any problem.

The quality of the product is , this person provides service, quality and reasonable price all the three things.

SARVESHWAR HERBALS LLP

I have good experience of work with these company. The product has very good quality.

The quality of the product is , this person provides service, quality and reasonable price all the three things.

COCOFIT PVT.LTD

He is the best person to purchase the dryer in all over India, he is taking my follow-up even after the delivery of the product whether I have any problem. he has provided the product on time also with reasonable price he is very genuine and honest

The quality of the product is , this person provides service, quality and reasonable price all the three things.