Monday – Friday: 9:00 am -8:00 pm

24/7 Emergency Service

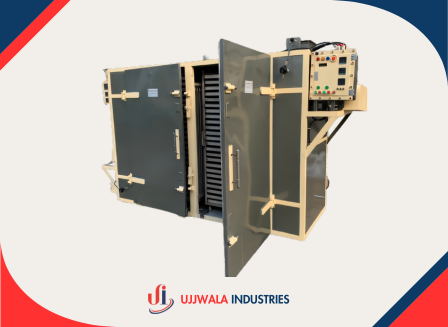

Flameproof Tray Dryer

Use Of Product / Advantages

Chemical Industry:

Drying of volatile or flammable chemicals where there is a risk of combustion or explosion during the drying process. This is critical in industries dealing with solvents, reactive chemicals, or materials with low flash points.

Pharmaceuticals:

Drying of pharmaceutical products that involve flammable solvents or reactive substances. Flameproof tray dryers provide a secure environment for the drying of such materials, ensuring safety in pharmaceutical production processes.

Explosive Powders:

Drying of explosive powders or materials that have the potential to combust when exposed to heat or specific environmental conditions. The flameproof design helps prevent the risk of ignition.

Hazardous Waste Treatment:

Drying of hazardous waste materials that may pose a risk of combustion or explosion. Flameproof tray dryers are used to process and treat such materials in a controlled and safe manner.

Research and Development:

In laboratories and research facilities, flameproof tray dryers are used for drying experiments involving flammable or explosive materials. This ensures a safe environment for researchers conducting experiments with reactive substances.

Petrochemical Industry:

Drying of petrochemical products or by-products that may be flammable or explosive. Flameproof tray dryers are employed in refineries and petrochemical plants to ensure the safety of drying processes.

Paint and Coatings:

Drying of paint and coatings containing volatile solvents. Flameproof tray dryers are used to eliminate the risk of fire or explosion during the drying of solvent-based paint and coating formulations.

Adhesives and Sealants:

Drying of adhesives and sealants that may contain flammable components. Flameproof tray dryers provide a safe environment for the drying of these materials in the manufacturing process.

Aerospace Industry:

Drying of materials used in the aerospace industry, such as propellants or coatings, which may have flammable properties. Flameproof tray dryers help mitigate the risk of fire or explosion in these applications.

Safety Standards Compliance:

Industries that need to comply with strict safety standards and regulations may use flameproof tray dryers to meet safety requirements and prevent accidents related to flammable materials.

It's crucial to note that the use of flameproof tray dryers is dictated by the specific safety requirements of the materials being processed and the regulatory standards applicable to the industry. These dryers are designed with safety features, including explosion-proof electrical components, reinforced construction, and other measures to minimize the risk of fire or explosion. Proper training and adherence to safety protocols are essential when working with such

Batch Processing: Ideal for small batches and varied products.

Equipment Uniform Drying: The controlled airflow ensures uniform drying across all trays.

Easy Monitoring: Transparent chamber allows visual inspection during drying.

Applications

Tray Dryers are ideally suitable for drying pharmaceuticals, chemicals, powders, granules, plastic granules etc. Heating is either by electric or steam or both combined. Various models are listed in this leaflet to suit customer requirements. Custombuilt models can be quoted on request.

Features

Flameproof Construction: The entire structure of the tray dryer is constructed to be flameproof, meaning it is designed to contain any potential ignition or explosion within the unit. This construction involves using flameproof materials and reinforced construction.

Explosion-Proof Electrical Components: The electrical components within the flameproof tray dryer, including motors, switches, and other electrical elements, are designed to be explosion-proof. This means they are constructed and sealed in a way that prevents the release of sparks or heat that could potentially ignite flammable materials.

Spark-Proof Design: Components like fans and motors are designed to be spark-proof, minimizing the risk of sparks that could potentially ignite flammable materials.

Specialized Gaskets and Seals: Gaskets and seals used in the tray dryer are specially designed to prevent the leakage of gases or vapors. These seals contribute to the overall containment of the drying chamber.

Drying Chamber: Similar to conventional tray dryers, a flameproof tray dryer contains a drying chamber where trays or racks can be placed to hold the materials being dried.

Trays or Racks: These are the components on which the materials are loaded for drying. They are designed to be flameproof and may be made from materials that minimize the risk of static electricity buildup.

Air Circulation System: A fan or blower system circulates air within the drying chamber. This system is designed to be spark-resistant and prevent the generation of sparks that could lead to ignition.

Heating System: The heating system is responsible for generating the warm air needed for the drying process. It may include flameproof electric heaters, steam coils, or other heat sources that are designed to minimize the risk of ignition.

Temperature and Humidity Sensors: Sensors placed within the drying chamber monitor temperature and humidity levels. These sensors are designed to be intrinsically safe and avoid generating sparks or heat.

Control Panel with Safety Features: The control panel includes safety features such as over-temperature protection, emergency stop buttons, and alarms. These features help ensure that the drying process remains within safe parameters.

Variable Speed Control (For Some Dryers): Some Flamproof Tray Dryer offer variable speed control to adjust the drying based on the specific requirements of the material being processed.

Technical Specifications

| Loading capacity | 10-12 Trays | 20-24 Trays | 25 Trays | 48-50 Trays | 96-100 Trays | 192-200 Trays |

|---|---|---|---|---|---|---|

| No of Doors | One | One | One | One | Two | Two |

| No of Blowers | Two | Two | Two | Two | Two | Four |

| No of motors / H.P.3 Phase 415 Volts . | 2/ 0.5 H.P.single phase 240 volt 1400 rpm | 2 / 0.5 H.P.single phase 240 volts 240 rpm | 2 / 0.5 H.P.single phase 240 volts 240 rpm | 2/1 H.P.Three phase 415 volts 1400 rpm | 2/1 H.P.Three phase 415 volts 1400 rpm | 2 / 2 H.P.eachThree phase 415 volts 1400 rpm |

| Electrical Heating Load for 100 ° C / 200 ° C / 300 ° C | 3kw | 6kw | 8kw | 12kw | 24kw | 36kw |

| Insulation in mm100 ° C / 200 ° C / 300 ° C | 50 | 50 | 50 | 75 | 75 | 75 |

| No of Trolleys | Rack System | Rack System | Rack System | One | Two | Four |

| Tray Size | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch | 32x16x1.5 Inch |

| Trolley Dimension | Fixed Racks | Fixed Racks | Fixed Racks | Movable Trolley | Movable Trolley | Movable Trolley |

Featured Products

Product Brochures

Illuminating Lives with Quality Products for a Brighter Tomorrow.

Intas Pharmaceuticals

I recently purchased a Ujjwala Industries Tray Dryer Machine and I am very pleased with my purchase. The machine is well-constructed and easy to use. It is designed to quickly and efficiently dry a variety of items such as fruits, vegetables, and herbs. The temperature settings are adjustable and the machine is equipped with a timer.

Rashtriya metal industries ltd

Best Vendor i have ever got till date. He is very genuine, honest person, gives me delivery on time also he is continuously taking my follow-up post delivery whether I have any problem.

The quality of the product is , this person provides service, quality and reasonable price all the three things.

SARVESHWAR HERBALS LLP

I have good experience of work with these company. The product has very good quality.

The quality of the product is , this person provides service, quality and reasonable price all the three things.

COCOFIT PVT.LTD

He is the best person to purchase the dryer in all over India, he is taking my follow-up even after the delivery of the product whether I have any problem. he has provided the product on time also with reasonable price he is very genuine and honest

The quality of the product is , this person provides service, quality and reasonable price all the three things.